SPECIALIZING IN:

Value Engineering | Specs Crossovers | Out-of-Stock Replications | Overbudget Replications

ASL’s one-of-a-kind production process allows you the freedom to make changes as you see fit – a flexibility that is virtually unmatched in the industry.

1,000,000+ options.

From designer lighting to specialty fixtures and beyond, our in-house engineers and lighting artisans work hand-in-hand to develop and craft your vision.

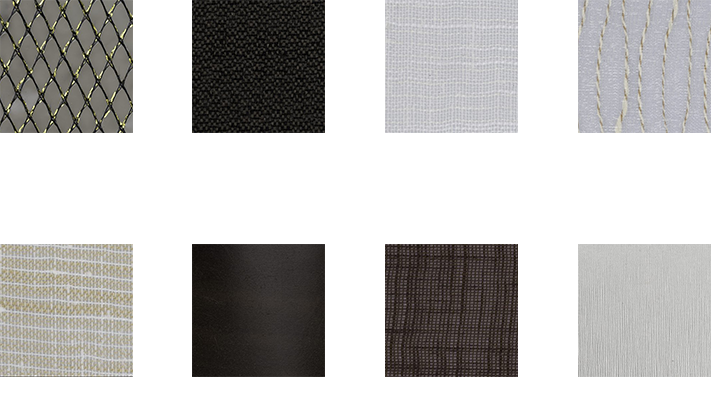

While we can create your fixture in almost any finish, here are some of our more standard and popular options.

Details make all the difference. Customize those for any fixture.

Energy efficiency is our specialty. Our wide range of available drivers covers your every application need.

Our trained technicians are capable of molding lenses for precise applications and are skilled with glass, acrylic, and a bevy of other materials.

Most ASL fixtures use between 110-140 lumens per watt, and wattage can be customized according to need.

Whether you seek bright light or a warm glow, we can fine-tune virtually any light source to suit your needs.

Swap out any bulb with the one you need. Options are limitless.

SPECIALIZING IN:

Value Engineering | Specs Crossovers | Out-of-Stock Replications | Overbudget Replications

Our in-house lighting engineers are skilled in bringing concepts to light, from adapting designer sketches into production-ready drawings, to developing AutoCAD files and 3D modelings, to iterating more cost-effective and energy-efficient versions of existing models.

When a high level of precision is needed, our team applies Computer Numerical Control (CNC) Machining to cut and shape the metal components of your fixture. Because such lighting is often installed in harsh, high-pressure, or dusty environments, we meticulously fabricate these to be waterproof and airtight.

Our high-precision laser machinery is capable of cutting any shape or pattern. These machines cut plates following any template, with the capacity to fill orders speedily - from small runs to large production.

At our welding work stations, trained technicians work in line with the most detailed specifications. We specialize in fusing diverse materials as well as spot welding for superior durability and craftsmanship.

Our high-capacity polishing equipment ensures metal components are completed with a smooth finish. For more high-end, detailed, or delicate fixtures, trained ASL technicians complete the polishing process by hand.

With artistic flair and meticulous attention to detail, our in-house artisans apply breathtaking finishes, including natural-looking wood, stone, and textured surfacing.

For large-scale components, our spray shop provides the finishing touch, with high-quality coatings such as weather-resistant epoxy, anodization and more.

Prior to applying paint and other finishings, metal is sandblasted to ensure longevity. Additionally, glass and acrylic components can be sandblasted to add textures or patterns.

Our fixtures are manufactured to the highest standards of safety and compliance and are UL approved and certified ADA compliant.

Our team is experienced in packing and shipping even the most delicate lighting. Every fixture is prepped and packed individually and carefully to prevent damage during transport. For easy installation, each fixture is packed as assembled as possible, and together with all its components.

Using only leading brands prevents expensive burnouts and failures.